Heat shrink tubing is one of the simplest yet most effective solutions for protecting, insulating, and reinforcing electrical and mechanical components. Knowing how to use heat shrink tubing properly can make the difference between a connection that is safe, reliable, and durable, and one that fails when exposed to heat, moisture, or mechanical stress. While it is often used in electrical work, its versatility makes it valuable in fields ranging from automotive repair and aerospace wiring to hobby electronics and even medical devices.

The first step in using heat shrink tubing is choosing the right size. Tubing is available in different diameters and shrink ratios, most commonly 2:1 or 3:1, which describe how much the tubing will contract when heated. A 2:1 ratio means that the tubing will shrink to half of its original diameter, while a 3:1 ratio means it will shrink to one-third. Selecting tubing that is too large can result in a loose fit that does not provide proper insulation, while choosing tubing that is too small may make it difficult to slide over the wire or connector in the first place. The general rule is to select tubing that is about 25 to 50 percent larger than the component it needs to cover before shrinking.

Once the correct size is selected, preparation becomes critical. The wire, joint, or component should be cleaned thoroughly to remove dirt, grease, or oxidation, since contaminants can interfere with the tubing’s ability to conform tightly. If the tubing is being applied to a soldered joint, it is best to cut a length of tubing before soldering, slide it onto the wire, and then move it into place after the joint has cooled. This prevents the need to reheat the joint unnecessarily and avoids damage to the tubing. For mechanical applications, such as covering a splice or protecting a small tool handle, cutting the tubing with a clean, sharp edge ensures a smooth finish when it shrinks.

Positioning is straightforward but requires attention. The tubing should be centered over the area to be protected, with equal coverage on both sides of the joint or exposed section. In some cases, layering multiple pieces of tubing provides additional reinforcement or color coding, which is particularly useful in cable management or multi-wire harnesses.

Applying heat is the most important stage. The most reliable tool is a heat gun because it provides controlled, evenly distributed hot air without direct flame contact. Some people use lighters or torches, but this is risky because open flames can scorch or overheat the tubing, causing it to char or become brittle. To apply the tubing correctly, the heat gun should be moved slowly back and forth along the length of the tubing, allowing it to shrink gradually and evenly. Concentrating heat in one spot can lead to bubbles, uneven contraction, or even damage to the wire insulation underneath.

As the tubing shrinks, it will begin to conform tightly around the underlying material. The goal is a smooth, uniform layer without wrinkles or gaps. This process is easy to observe, as the tubing becomes visibly smaller and grips the surface firmly. Once the tubing has fully contracted, it is important to let it cool naturally. Rapid cooling, such as by blowing cold air or placing the part in water, can create internal stresses that might weaken the bond.

Using heat shrink tubing is not just about covering exposed wires. It also provides mechanical strain relief, protecting joints and connectors from bending or pulling forces. In automotive or aerospace applications, where vibration is common, the tubing adds strength and extends the lifespan of the connection. In electronics, it helps prevent short circuits by sealing exposed conductors. Some specialized heat shrink tubing also has an adhesive lining, which melts during the shrinking process and forms a waterproof seal, making it ideal for outdoor or marine environments.

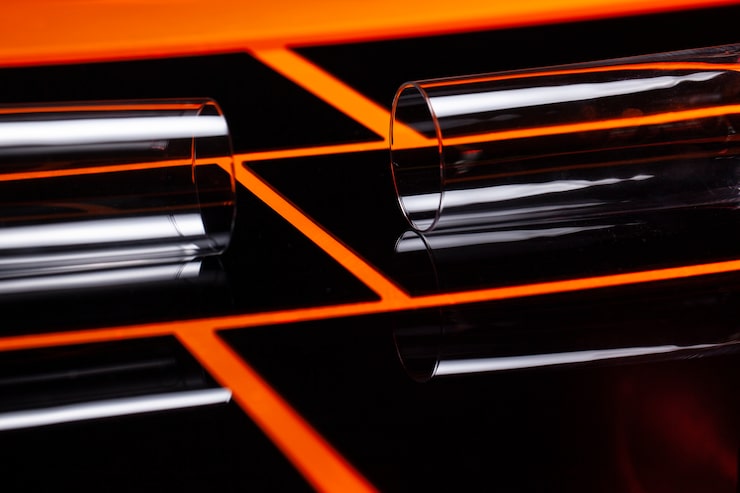

Another key benefit is organization and identification. Different colors of tubing can be used to code wires or group cables together neatly. Transparent tubing is available as well, which allows labels or identification marks on wires to remain visible after shrinking. In repair work, heat shrink tubing can also be used to restore insulation on damaged cables, giving them a second life without replacing the entire assembly.

Safety should always be kept in mind. Working with high temperatures requires caution, so protective gloves are recommended, especially if multiple joints are being insulated in sequence. Adequate ventilation is also important, as heating any plastic can release small amounts of fumes. For sensitive electronics, care should be taken not to overheat nearby components.

The process may appear simple, but using heat shrink tubing correctly offers long-term reliability. A poorly shrunk piece that is loose or uneven may allow moisture or dust to penetrate, defeating the purpose of protection. On the other hand, when applied with care, the tubing forms a professional-grade seal that is durable, electrically safe, and mechanically strong.

In practice, once you understand the basics—selecting the correct size, preparing the surface, positioning the tubing, applying controlled heat, and allowing it to cool—heat shrink tubing becomes a quick and reliable solution for countless applications. Whether you are a professional electrician, an engineer, or a hobbyist working on home projects, mastering this simple material provides an inexpensive way to ensure safety, durability, and organization in your work.