In industrial finishing, understanding what is the difference between powder coating and electrostatic coating is fundamental for selecting the right surface treatment. While the terms are often used interchangeably, they describe different aspects of the coating process, materials, and application methods.

Powder coating refers to the type of material used. It is a dry particulate coating composed of resin, pigment, and additives. Once applied to a surface and cured in an oven, the powder melts and forms a continuous, durable film. Powder coatings are known for their excellent corrosion resistance, mechanical strength, and aesthetic versatility. They can be formulated to provide gloss, texture, or color stability and are widely used in automotive, appliances, furniture, and industrial equipment.

Electrostatic coating, on the other hand, refers to the method of applying the coating, whether powder or liquid. In this process, the coating particles are given an electrical charge, typically positive, and the target surface is grounded. The electrostatic attraction ensures uniform coverage, even on complex geometries, and improves transfer efficiency by minimizing overspray. Electrostatic coating is a technique rather than a material type; it can be used with both powder coatings and certain liquid paints.

The key difference lies in material versus method. Powder coating is the substance that forms the protective and aesthetic layer, while electrostatic coating is the application technique that ensures adherence, uniformity, and efficiency. A powder coating can be applied electrostatically or using other methods, but electrostatic application maximizes efficiency and quality. Conversely, electrostatic methods can be used with liquid paints to improve coverage and reduce waste.

Electrostatic application provides several advantages for both powder and liquid coatings. It allows for even distribution, minimizes waste, and enhances adhesion on difficult-to-reach surfaces. For manufacturers, this translates to more consistent quality, reduced material costs, and fewer reworks. Combined with powder coating, electrostatic methods produce a highly efficient and environmentally friendly system.

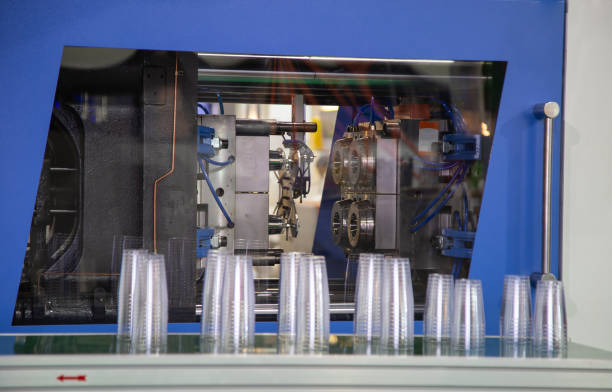

Applications of powder coating applied electrostatically include metal furniture, automotive components, machinery, and appliances. Industries that demand durability, corrosion resistance, and aesthetic appeal frequently rely on electrostatic powder coating systems to meet high production standards.

In summary, the difference between the two is that powder coating is the material used to protect and decorate a surface, while electrostatic coating is the process used to apply the material efficiently and uniformly. Understanding this distinction helps manufacturers select the best combination of material and technique for their application, balancing durability, appearance, and cost-effectiveness.