Electrostatic powder plays a critical role in modern coating technologies, and understanding what is electrostatic powder is essential for professionals in manufacturing, automotive, construction, and electronics industries. Unlike liquid coatings, electrostatic powder is a dry particulate material that is applied to surfaces using electrical charges, resulting in a durable and uniform finish.

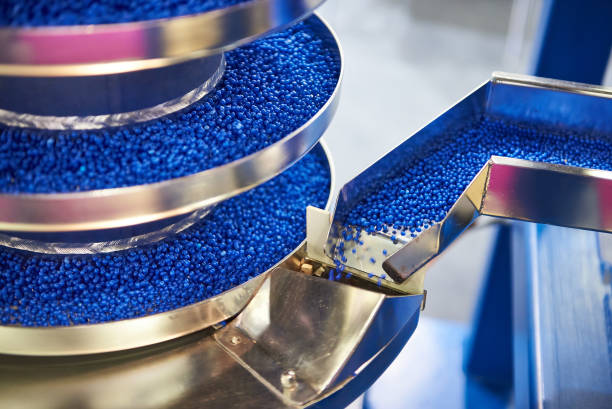

Electrostatic powder is typically composed of resin, pigment, and additives. The resin forms the protective layer, pigments provide color and aesthetics, and additives enhance properties such as adhesion, corrosion resistance, or UV stability. The powder particles are very fine, which allows them to adhere evenly when applied using an electrostatic process.

The defining feature of electrostatic powder is its application method. Powder particles are given a positive electrical charge as they exit the spray gun. The target surface is grounded, creating an electrostatic attraction between the powder and the object. This ensures that the coating adheres uniformly, even to complex shapes or areas that are difficult to reach with traditional liquid paint. Once applied, the coated item is heated in an oven, causing the powder to melt and flow, forming a continuous, durable film.

One of the key advantages of electrostatic powder is its environmental efficiency. Unlike liquid paints, which can contain volatile organic compounds (VOCs) that evaporate into the atmosphere, powder coatings are nearly 100% transfer efficient. Overspray can be collected and reused, reducing waste and minimizing environmental impact. This makes electrostatic powder coatings attractive for industries seeking sustainable production methods.

Electrostatic powders are available in a wide range of resin types, including polyester, epoxy, polyurethane, and hybrid formulations. Each type offers specific properties: epoxy powders provide excellent chemical and corrosion resistance, polyester powders offer UV stability and outdoor durability, and polyurethane powders deliver flexibility and toughness. Manufacturers can select the appropriate powder based on the application, environmental conditions, and required performance characteristics.

In addition to durability, electrostatic powder provides aesthetic versatility. The powder can be formulated in multiple colors, textures, and finishes, including smooth, matte, gloss, metallic, or textured surfaces. This makes it ideal for both functional and decorative applications, from industrial machinery to consumer electronics, automotive parts, and furniture.

Application of electrostatic powder also improves mechanical performance. The coating forms a uniform, thick layer that resists chipping, scratching, and abrasion. This is particularly valuable for high-wear components such as metal furniture, outdoor equipment, or industrial machinery, where long-term protection is critical.

The process of working with electrostatic powder requires attention to surface preparation, grounding, and curing. Proper cleaning and preparation of the substrate ensure adhesion, while correct oven curing ensures that the powder melts and cross-links effectively. Modern electrostatic powder systems are often automated, providing precise control over particle charge, spray patterns, and coating thickness.

Electrostatic powder coatings are widely adopted across multiple industries. In construction, they protect metal structures, railings, and frames. In automotive manufacturing, they provide corrosion resistance and aesthetic finishes. In electronics, they insulate and protect components. The combination of efficiency, durability, and environmental benefits makes electrostatic powder a preferred choice for modern coating applications.

From an industrial perspective, the growing demand for sustainable and high-performance coatings continues to drive innovations in electrostatic powder formulations and application technologies. Manufacturers are developing powders with enhanced corrosion resistance, heat resistance, and specialized textures, expanding their range of applications and performance capabilities.