When businesses consider entering the field of plastic manufacturing or expanding their existing capabilities, one of the most frequently asked questions is: How much does plastic extrusion cost? Whether you're looking to produce custom plastic profiles, pipes, sheets, or films, understanding the total cost structure is essential for budgeting, pricing, and long-term planning. This article provides an in-depth exploration of the costs involved in plastic extrusion, especially for those considering investing in an extruder for plastic.

Understanding Plastic Extrusion

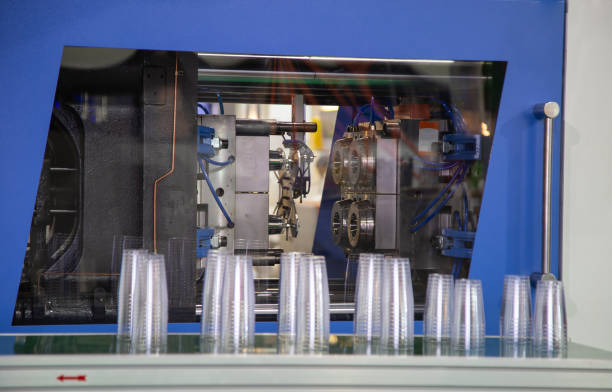

Plastic extrusion is a manufacturing process where raw plastic material—typically in the form of pellets—is melted and pushed through a shaped die to form a continuous profile. This method is widely used in the production of plastic pipes, tubing, sheets, window frames, wire insulation, and many other products. At the core of this process is the extruder for plastic, a machine that heats, mixes, and pushes the molten polymer through a die to create consistent shapes.

Key Factors Affecting Plastic Extrusion Costs

Plastic extrusion costs are influenced by a range of interrelated variables. Each factor can significantly impact the final cost per unit and the upfront investment required.

1. Equipment Cost

The price of an extruder for plastic varies widely depending on its size, type, production capacity, and degree of automation. For example:

Small-scale or benchtop extruders typically range from $10,000 to $50,000, ideal for research labs or small-batch production.

Medium-capacity extruders designed for producing pipes, rods, or profiles may cost between $50,000 and $150,000. These are commonly used by mid-sized manufacturers with regular production volumes.

High-output industrial extrusion lines can exceed $200,000, especially if they include advanced features such as automatic feeders, gravimetric blending systems, and multi-layer co-extrusion capabilities.

Additional equipment like die heads, vacuum sizing tanks, water cooling baths, caterpillar pullers, and winders must also be considered as part of the capital investment. These components ensure smooth and consistent production, and their quality and durability directly affect operational efficiency.

2. Raw Material Costs

Material cost is one of the largest ongoing expenses in plastic extrusion. The type of polymer used will greatly influence the cost structure. Common extrusion plastics include:

Polyethylene (PE)

Polypropylene (PP)

Polyvinyl chloride (PVC)

Polystyrene (PS)

Acrylonitrile butadiene styrene (ABS)

Thermoplastic polyurethane (TPU)

Typical prices for these materials can range from $1.00 to $3.00 per kilogram, though specialty polymers or bio-based alternatives may cost more. The use of recycled materials can help lower costs, but may also affect product quality and consistency.

For example, a manufacturer extruding high-density polyethylene (HDPE) pipes at 500 kg per hour would spend approximately $500 to $1,500 per hour on raw materials alone, depending on market conditions.

3. Labor and Operational Costs

Operating a plastic extrusion line requires skilled labor for setup, monitoring, and maintenance. Labor costs vary by region but may average $20 to $50 per hour per technician. In some operations, one technician can oversee multiple machines, reducing per-unit labor cost.

Energy consumption is another crucial factor. Extrusion machines typically require electrical power between 30 kW and 150 kW, depending on their size and throughput. Monthly electricity expenses for an industrial extrusion line can exceed $5,000, especially when running multiple shifts.

Maintenance, lubricants, cleaning supplies, and spare parts also add to the operational expenses, with annual maintenance costs averaging 2% to 5% of the machine’s initial value.

4. Tooling and Die Costs

Each product you manufacture requires a specific die, which can range from $1,000 to over $20,000, depending on complexity and size. Custom dies for multi-layer or co-extruded products are more expensive due to the engineering required. High-quality dies ensure precise dimensions, smooth finishes, and efficient production.

Tooling costs should be considered as part of the startup expenses for any new product line and may require several revisions to achieve the desired output.

5. Packaging and Logistics

Once the product is extruded and cooled, it must be cut, coiled, or packaged depending on its final use. Packaging materials, labeling, and shipping can add another 5% to 10% to your total product cost. Long-distance logistics, especially for bulky extruded profiles, can significantly impact profit margins.

Businesses exporting to international markets must also factor in customs duties, taxes, and transportation insurance.

6. Production Volume and Efficiency

High-volume production typically reduces the cost per unit. Efficient extrusion lines that minimize downtime, material waste, and product defects can dramatically improve profitability. Investing in automated controls, real-time monitoring systems, and quality inspection tools can reduce rework and improve consistency.

A well-optimized extrusion operation may produce high-quality profiles at costs as low as $0.30 to $1.00 per meter, depending on material choice and product type. Conversely, inefficient or small-scale operations might experience much higher unit costs, making them less competitive in the market.

7. Compliance and Certifications

Certain industries—such as food packaging, construction, or automotive—require compliance with strict quality, safety, or environmental standards. Achieving certifications like ISO 9001, UL, RoHS, or FDA approval may involve additional testing, documentation, and process control investments.

These certifications are often necessary for entering high-value markets and should be factored into your overall cost planning.

Final Thoughts: Cost vs. Value

The question “How much does plastic extrusion cost?” cannot be answered with a simple figure. It depends on many variables, including equipment size, product type, raw material choices, and operational efficiency.

For those considering investing in an extruder for plastic, the decision should be based not only on the initial capital cost but also on the long-term value it brings. A reliable, high-quality extrusion line can deliver consistent returns for years, provided it's matched to your specific production needs and managed effectively.

Understanding all aspects of cost helps manufacturers make informed decisions, avoid unexpected expenses, and maintain competitive pricing in a demanding market. By balancing capital investment with operational excellence, plastic extrusion can be a highly profitable and scalable manufacturing solution.