Foamcore PVC is a lightweight and rigid plastic material widely used across various industries due to its unique structure and versatile properties. At its core, foamcore PVC consists of a cellular or foamed plastic core, sandwiched between two solid PVC outer layers. This combination results in a panel that is both strong and lightweight, providing a perfect balance for applications requiring durability without excessive weight.

One of the key features of foamcore PVC is its high strength-to-weight ratio. Unlike solid PVC sheets, which can be heavy and difficult to handle, foamcore PVC maintains excellent rigidity while significantly reducing overall weight. This makes it highly desirable for uses such as signage, display boards, architectural models, and other areas where ease of installation and transport are critical.

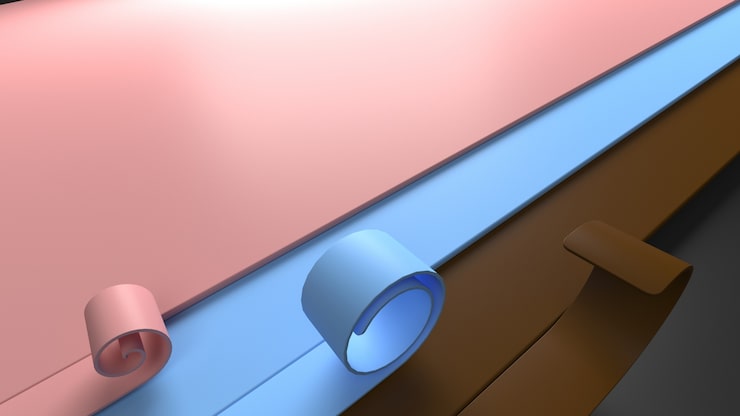

The manufacturing process of foamcore PVC typically involves co-extrusion, where the dense, durable PVC skins are bonded to a lightweight foamed core. This technique ensures the integrity and consistency of the material, resulting in panels that are resistant to warping, cracking, and impact damage. The foam core itself is made by introducing gas or blowing agents into the PVC during extrusion, creating a cellular structure that reduces density without compromising stability.

Another important advantage of foamcore PVC is its excellent chemical and moisture resistance. It does not absorb water, which prevents swelling or deterioration even in humid or wet environments. This makes foamcore PVC suitable for both indoor and outdoor applications, where exposure to weather or chemicals might otherwise damage other materials. Furthermore, foamcore PVC exhibits good resistance to UV radiation, helping maintain its appearance and structural integrity over time when used outdoors.

The surface finish of foamcore PVC is smooth and easy to work with, which enhances its versatility. It can be readily painted, printed on, or laminated, allowing it to serve as an excellent base for advertising, graphics, and decorative panels. This adaptability has led to its widespread adoption in the fields of marketing, exhibition design, and interior decoration.

In addition to its functional properties, foamcore PVC offers ease of fabrication. It can be cut, routed, drilled, and shaped with standard woodworking or plastic processing tools. This means manufacturers and fabricators can produce custom shapes and designs without much difficulty, reducing production time and costs.

For industries focused on sustainability, it is worth noting that foamcore PVC can be recycled and reused in certain processes. Though PVC itself poses some environmental challenges, advancements in recycling technologies have made it more feasible to repurpose foamcore PVC scrap and reduce waste.

Common applications of foamcore PVC include signage panels, where the lightweight nature allows for easy mounting and replacement. It is also popular in trade show displays, where portability and impact resistance are vital. Additionally, foamcore PVC is used in architectural modeling and prototyping, providing designers and engineers with a material that combines sturdiness and ease of manipulation. In the furniture and construction sectors, foamcore PVC is sometimes used for decorative wall panels or partitioning, offering an economical alternative to heavier or more fragile materials.

Despite its many benefits, users should be aware of certain limitations. Foamcore PVC, while resistant to many chemicals, may not withstand prolonged exposure to harsh solvents or extreme heat. Its maximum service temperature generally ranges between 60 and 70 degrees Celsius, so it is not suited for applications involving high thermal loads. Also, although the foam core enhances weight reduction, it may not provide the same load-bearing capacity as fully solid materials in demanding structural applications.

In summary, foamcore PVC is a versatile, durable, and lightweight material that serves a wide range of commercial and industrial purposes. Its unique structure of a foamed core sandwiched by solid PVC layers offers an excellent combination of strength, moisture resistance, and ease of handling. This makes it especially valuable for applications like signage, displays, architectural modeling, and decorative panels. Understanding its properties, fabrication options, and limitations allows businesses and designers to maximize the benefits of foamcore PVC, ensuring cost-effective and high-quality results.

As industries continue to seek materials that balance performance with practicality, foamcore PVC remains a leading choice. Its adaptability to various finishing techniques and its resistance to environmental factors make it a smart investment for projects requiring both durability and aesthetic appeal. Whether for indoor or outdoor use, foamcore PVC delivers reliable performance that meets the evolving needs of modern manufacturing and design.