High density polyethylene known as HDPE is a versatile thermoplastic widely used in various industries due to its excellent mechanical properties chemical resistance and durability One common manufacturing process for HDPE products is extrusion which allows shaping this material into continuous profiles such as pipes sheets films and other forms

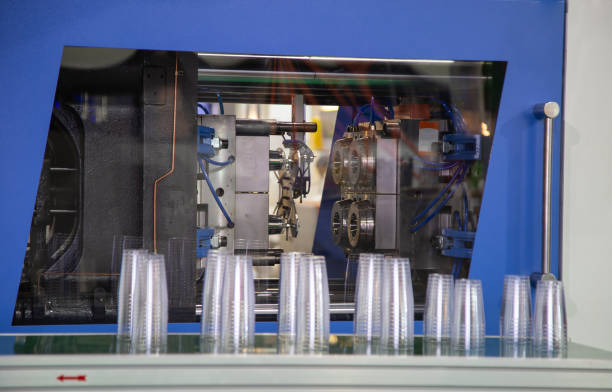

Extrusion of HDPE involves melting the plastic pellets by heating them inside an extruder barrel The molten polymer is then forced through a die that shapes it into the desired cross-sectional profile After exiting the die the extruded material cools and solidifies maintaining the shape defined by the die The process is continuous and efficient making it suitable for mass production

The ability to extrude HDPE depends on several factors including the quality of the raw material extrusion machine specifications temperature control and die design HDPE has a relatively high melting point compared to other polyethylene types so precise temperature management is critical to avoid degradation or incomplete melting Improper temperature can lead to defects like bubbles surface roughness or weak mechanical properties

Using modern extrusion equipment with accurate heating zones and variable screw speeds enhances control over the process Parameters such as melt pressure melt temperature and cooling rate must be monitored continuously to ensure consistent product quality Additionally the purity of HDPE pellets affects extrusion stability as contaminants can clog the die or cause irregular flow

Extruded HDPE products benefit from the material’s inherent properties including excellent chemical resistance resistance to impact and good electrical insulating characteristics These features make extruded HDPE pipes ideal for water and gas distribution systems where durability and corrosion resistance are essential The material’s flexibility and toughness also enable it to withstand environmental stresses over long periods

In industrial applications extrusion allows the production of custom shapes and sizes beyond pipes such as sheets used in packaging or films for protective layers This versatility is why HDPE extrusion is a preferred method in sectors requiring reliable lightweight and cost-effective plastic components

Challenges in extruding HDPE include maintaining consistent melting without overheating preventing contamination ensuring uniform flow through the die and cooling the product quickly enough to retain its shape but slowly enough to avoid internal stresses The process demands skilled operators and well-maintained machinery for optimal results

In summary extrusion of HDPE is not only possible but widely practiced with appropriate equipment and process control This manufacturing technique leverages HDPE’s properties to produce durable efficient and versatile plastic products serving a broad range of industries Understanding the extrusion process helps manufacturers optimize quality reduce waste and meet market demands effectively