Products Description

This new type of seamless hot-melt sleeve is a novel hot-melt pipe fitting independently developed. Its base material is polyethylene, processed through biaxial stretching. The thickness of the fitting's base material is the same as the pipe substrate, but its strength is increased by more than 20%. During construction, only a flame gun is used for heating; after shrinking, the fitting tightly connects to the pipe, fully meeting the standards for airtightness testing. If the pipe deforms at the port during foaming or transportation, the hot-melt sleeve may not pass the airtightness test 100% after welding. In this case, 100mm wide heat-shrinkable tape can be used on both sides of the seamless hot-melt sleeve for auxiliary reinforcement, ensuring the joint passes the airtightness test 100%. Alternatively, heating elements can be placed on the base material for secondary heating to complete the hot-melt process, thus ensuring the airtightness test passes.

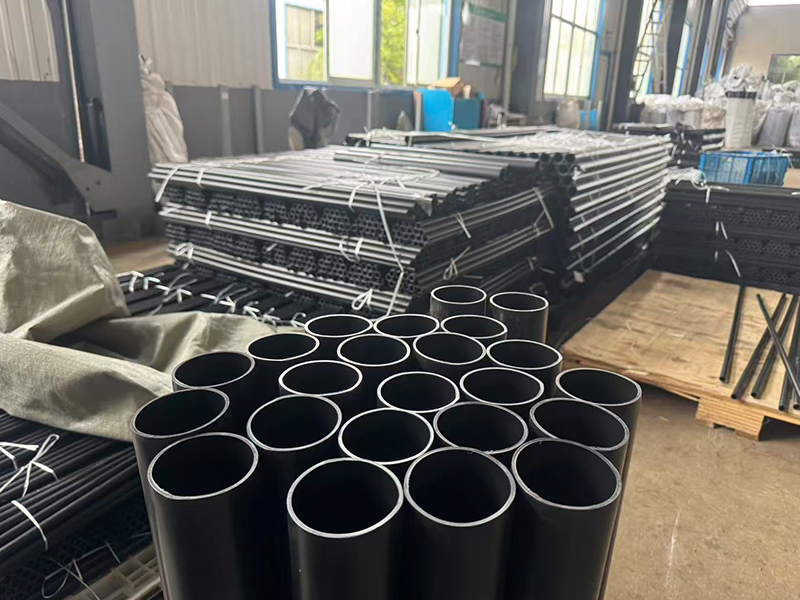

As a professional manufacturer of pipeline protection solutions in China, we take pride in owning a top-tier laboratory dedicated to strict quality control, ensuring consistent product performance. Our core product line, including seamless heat shrink sleeves, heat shrink tubes, and heat shrink bands, boasts four competitive edges that set us apart in the global market:

Comprehensive Product Range & Full Specifications: We strictly adhere to international standards, covering diverse needs of pipeline projects.

Ultra-High Cost-Effectiveness: By integrating in-house irradiation, granulation, and gluing processes, we minimize production costs while maintaining quality.

Rapid Delivery: We optimize our supply chain to meet tight project schedules for clients worldwide.

Industry-Leading Quality: Our products feature exceptional adhesion to steel—so strong that manual peeling is nearly impossible—effectively addressing a key industry pain point. This stable, top-tier quality has earned us trust from numerous global partners.